Characteristics of shape memory film

- High transparency

- Excellent elasticity

- Outstanding elastic recovery

- Permeability adequate for the application

- Film thickness 10 μm

- Film length 10 m to 300 m/roll

- Basic material polyethylene

Rotapack Zrt.

Highly stretchable, elastic up to break, excellent cling, outstanding load holding force, high tear and puncture resistance, material: polyethylene, can be collected selectively

Packaging cost reduction, less waste, safer transport, custom printing, UV protection, ESD, surface colouration in one layer after stretching

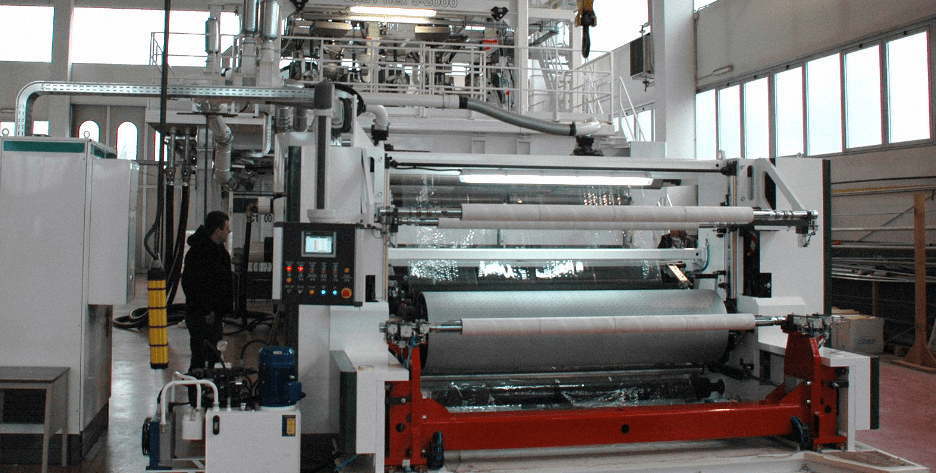

Cast, blown

12 μm to 30 μm

Cast, blown

10 μm to 30 μm

Are you interested in our product(s)? Do you have any questions?

The main objective of the research, financed within the framework of the programme GINOP-2.1.1-15-2015-00088, is the modification of the mechanical properties of the polyethylene raw material to approach those of soft PVC food wrap film. This film has good optical clarity, adequate flexibility and permeability. Beside all its advantages, recycling PVC is troublesome.

Reuse as food packaging material cannot come into question because of contamination, therefore it is considered first of all to be used in Energy from Waste (EfW) processes. During incineration, however, hydrogen chloride is released, and hydrogen chloride gives hydrochloric acid with moisture, which is very toxic and corrosive. Consequently, it is important to replace this packaging material with one based on polyolefin.

Among mechanical characteristics, emphasis was laid on the determination of the elastic modulus, elastic region and cling during research.

Within the framework of the project, particular attention was paid to environmental issues. Accordingly, recyclability of the materials produced during trials was also investigated.

Both polyethylene and PVC are manufactured from ethylene feedstock but, thanks to the differences in their manufacturing processes, they acquire different properties, which fact is

not to be neglected from the point of view of food safety. Polyethylene is produced by polymerisation of the ethylene gas, it is a combination of two elements, carbon and hydrogen. It can be used for producing industrial and household packaging materials without any additives. Thanks to its great stretch at break, it is excellent for wrapping loads of various shapes. Its unique low odour and liquid permeability is primarily based on special composition as well as production process.

Polyvinyl chloride (PVC) is produced by polymerization of the vinyl chloride monomer (VCM). As the name suggests, a great quantity of chlorine is added during process. When VCM is produced, mercury is released.

The film made of PVC is hard, rigid, decomposing when exposed to heat or light while decreasing strength, discolouring and releasing hydrochloric acid. Hence, stabilization is needed. To make PVC suitable for producing film and obtain characteristics indispensable from the point of view of wrapping, a dozen of additives (e.g. stabilizing agents, lubricants, plasticizers) are added, including carcinogenic substance(s) as well.

Use of wrapping materials based on soft polyethylene in food industry plays a major role since wrap is required to fulfil demands of freshness, quality, comfort and safety simultaneously and these requirements can only be met by resins. A few grams of film is enough to wrap a kilogram of fresh food.

Your message will be answered in 24 hours.